Our Sustainability Vision

We turn circularity into a reality.

We want to be part of the solution and drive sustainability: That’s why we are making textile-to-textile recycling a priority.

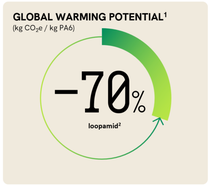

As a frontrunner in sustainability and circularity in the textiles industry, loopamid® is the answer for textile-to-textile recycling. We measure and verify the environmental impact of our products as part of our dedication to reducing our environmental footprint.

With loopamid® we offer a high-quality material for the textile production with a low product carbon footprint and entirely made from secondary raw materials (textile waste).

Together with our partners in the industry we are aiming to close the loop between the end-of-use phase and the raw materials phase by recycling worn apparel into new input materials.

Keeping the materials of textile products in the loop through recycling is crucial to reduce the environmental impacts of textile products.

1 Higg Index, 2 BASF Internal LCA assessment for commercial sale facility.

.jpg)

.jpg)